FILE - In this July 27, 2018, file photo, the Dave Johnston coal-fired power plant is silhouetted ... [+]

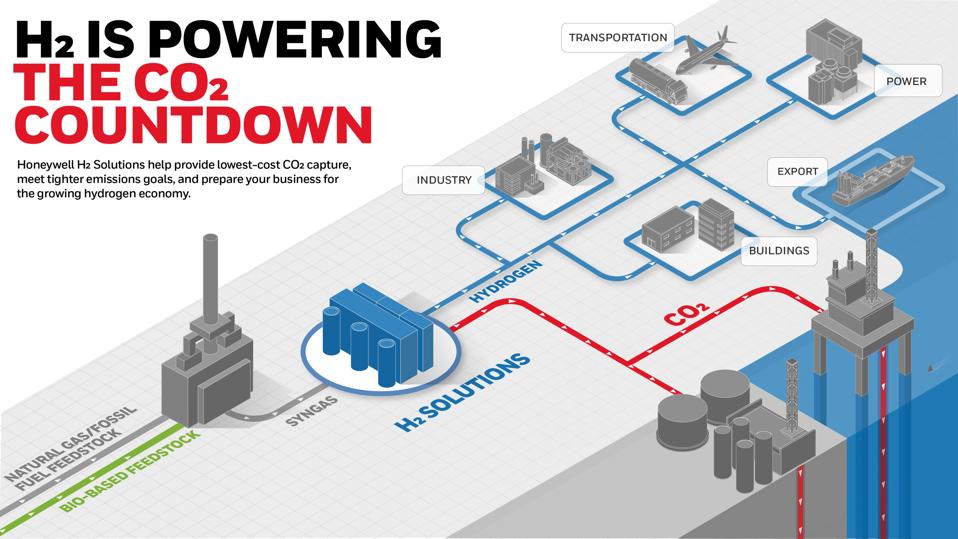

Talk about changing times. An old gasification plant in West Terre Haute, Indiana is getting a new life. It will use petroleum coke and biomass to produce hydrogen for power. It will also capture and sequester the resulting CO2. Just how realistic is this pursuit and just how clean is the process?

The developers say that it is viable. The hydrogen will be separated and the resulting energy is expected to be sold to power generators and chemical makers. Using a proprietary process, the CO2 will be captured and buried. It is a cost effective endeavor, they add, because it is repurposing an existing asset. It has also received both federal funding and federal tax credits.

"For all of those reasons this is a clean energy project that is likely to move forward,” says Beth Carter, senior business manager for clean hydrogen at Honeywell, in a Zoom conversation with this reporter. “These projects are commercially available today. The energy transition is not something that will happen in a decade or two. We are showing the world it is happening now and that it is important.”

It’s a dual operation between Wabash Valley Resources LLC and Honeywell UOP technologies to capture and sequester up to 1.65 million tons of CO2 a year. While it got funding from the Department of Energy’s "Carbon Storage Program," the companies said that this is small percentage of the overall $600 million cost. Meantime, the conversion of the gasification plant got started in 2020 and the developers expect the remodeled facility to generate 300 megawatts of electricity with net-zero CO2 emissions in 2024.

The Wabash River Generating Station was a 972.7-megawatt coal-fired power station operated by Duke Energy Indiana

The facelift is part of a larger effort to move into the hydrogen era. The Fuel Cell and Hydrogen Energy Association estimates that the hydrogen economy can generate revenues of $140 billion per year while also creating 700,000 U.S. jobs by 2030. At projected growth rates, revenues could be $750 billion per year while jobs could hit 3.4 million jobs by 2050.

Zeroing In On Cost

Wabash Valley Resources and Honeywell are teaming to produce hydrogen in Indiana. The fuel will be ... [+]

And advanced and remodeled plant could scrub the mercury, nitrogen oxide, and sulfur dioxide before it would separate the remaining byproducts: carbon dioxide, carbon monoxide, and hydrogen, which could be used to run everything from cars to power plants to ammonia production. The Boundary Dam in Estevan, Saskatchewan, Canada, for example, was the world’s first commercial carbon capture project. As for Honeywell, it says that its technology can remove almost all of the CO2 and permanently store it in porous rocks in the Illinois Basin.

Globally, 17 large-scale carbon capture and storage projects are in operation, says the Global CCS Institute. More are now under construction. Altogether, those ventures would seize about 40 million tons a year of CO2. The current ones are catching a pittance of the overall heat-trapping emissions. However, at least 6 billion metric tons of CO2 needs to be captured by 2050 to keep temperatures in line with the Paris climate accord, adds the International Energy Agency.

Statoil, for example, is placing 1 million tons of CO2 per year into a saline aquifer deep in the North Sea to enhance oil recovery. Meantime, ConocoPhillips

“The integration of biomass (corn stover) allows us to be net-zero on a lifecycle basis,” says Dan Williams, managing director for the Wabash Valley Resources in Terre Haute, during the Zoom call. “It needs to be replicated,” he adds, if the country is to meet its CO2 reduction targets. He supports the use of “petcoke” derived from oil refining as a feedstock, noting that it is typically disposed of as a waste product but that it will now become part of the “clean energy” cycle.

No doubt, the critics will take a whack at this project. For starters, they say that the resources are best plowed into developing renewable energy resources. Moreover, the IEA Clean Coal Center says that capturing and storing CO2 requires massive amounts of energy. That can become cost-prohibitive and can cause the cost of electricity to increase by up to 80%.

At the same time, they say that producing hydrogen from fossil fuels is too dirty. Instead of using such “grey hydrogen,” the attention needs to be on “green hydrogen” made from wind and solar — a process that uses electrolyzers to split apart the hydrogen and oxygen from the water where it is found.

The Learning Curve

LOS ANGELES, CA - JUNE 26: A pickup truck being filled with gasoline near a hydrogen fuel pump on ... [+]

Notably, 70 million tons of hydrogen are created each year: incredibly, 98% of that production comes from using carbon-intensive sources. Renewables, in contrast, are limitless and free — a strong incentive to leap to “green hydrogen.” Importantly, if fossil fuels are used as the feedstock to create hydrogen and if the CO2 emissions are captured and buried, it is referred to as “blue hydrogen” — the type of plant envisioned by Wabash Valley Resources.

Is there a role for blue hydrogen? “The only role I see is that it kicks the can down the road. It perpetuates the lie,” says Andrew Forrest, the founder of Australia’s Fortescue Metals Group, during a recent webinar.

The International Renewable Energy Agency says that energy losses occur when hydrogen is produced and transported: as much as 70% of the energy content may get lost, although that figure is less consequential if the hydrogen is created from solar power that is abundant and free. The agency concludes that per unit of energy, hydrogen supply costs are now 1.5 times to 5 times those of natural gas.

It adds that the learning curve linked to creating hydrogen is steep but worth it — no matter the fuel that is used. That is because it is all helping to expand the infrastructure that will carry the hydrogen to where it is consumed. That will reduce the need for new infrastructure investment, accelerating the transition from “grey hydrogen” to “green hydrogen.”

Take the Los Angeles Department of Water and Power, which will buy power from the so-called Intermountain Power Project in Utah that will generate green hydrogen from wind and solar: the plant will convert from a coal to a natural-gas combined-cycle facility that can also burn hydrogen as a fuel. By 2025, 30% of the electricity will come from green hydrogen, and by 2045, all of it will.

Moreover, a salt dome located on-site will store the hydrogen. When that fuel is needed, it can be accessed while the electricity is transported to Los Angeles via the existing transmission infrastructure.

As for Wabash Valley Resources, “In Indiana, state legislation has been passed supporting this project,” says Williams. “Indiana does not have a lot of wind and solar and this type of project is important.”

While carbon capture and sequestration is proving to be both elusive and expensive, the reality is that coal and natural gas make up 58% of the U.S. electricity generation pie. Meeting our climate goals necessitates the isolation of CO2 and the scaling up of green hydrogen production. That will come, though, with a high price tag — a cost that could pay off if the technologies advance and begin producing significant results.