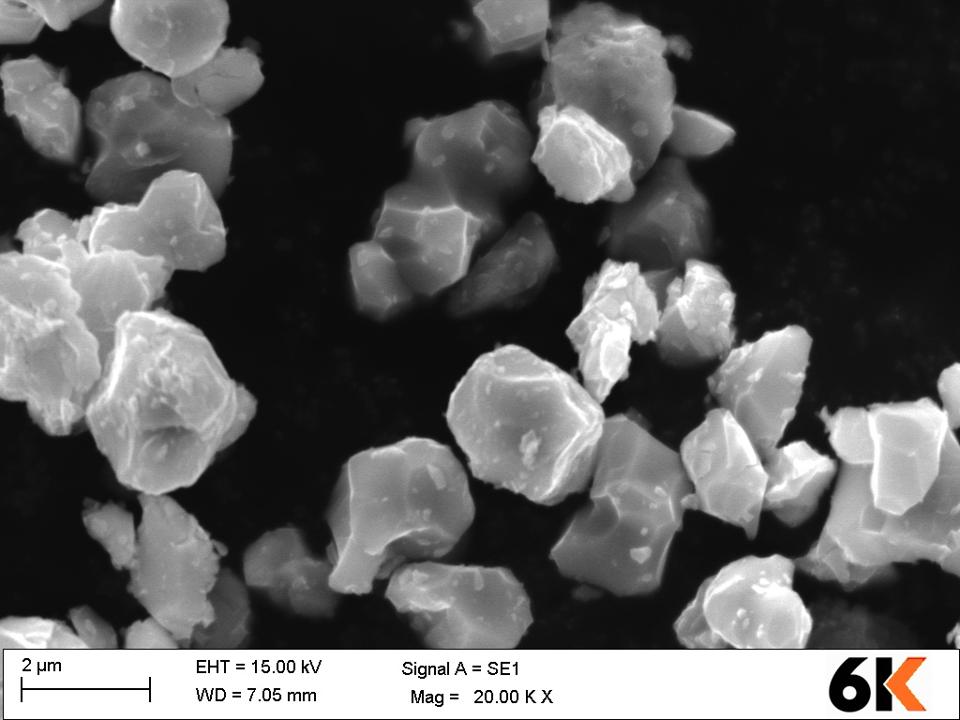

Nickel manganese cobalt (NMC) crystals made with 6K's UniMelt process.

The focus on EVs has accelerated recently, what with the recent unveiling of the electric Ford F-150 pickup and the new U.S. Postal Service delivery truck from Oshkosh Defense. And while there have been a good number of stories about how so many of the minerals that are critical for the “green economy” currently come from China, there’s been precious little attention paid to the facts that there is no production of core battery materials in America, and almost no domestic production of the batteries themselves. Critics, meanwhile, point to long charge times and a coming glut of end-of-life batteries as tremendous hurdles to the widespread adoption of EV technology.

6K says it has solutions for all of that. Based just outside Boston, the company is expanding its focus toward production of battery materials. In March it announced the establishment of a battery Center of Excellence for its 6K Energy division for that purpose, with plans to invest $25 million to bring battery production back to the U.S.

I previously covered 6K’s revolutionary new high-frequency microwave plasma metals production system–its UniMelt technology–and how that innovation could help meet the need for the high-quality metal feedstocks for advanced technologies such as 3D printing, while also establishing a circular economy for those materials. Building around that technology, the new battery Center of Excellence is addressing the urgency around domestic battery production, with ten UniMelt systems ranging from R&D to pilot-scale production, and innovative partnering models where 6K dedicates specific units for rapid customer integration and commercialization . “The pandemic was a wake-up call in a number of ways,” said 6K’s CEO Aaron Bent. “It brought a focus on national security, supply chain resilience, and critical materials. Now we’re out to prove batteries can be produced on U.S. soil. We’ve hired a new VP of Government Affairs and we’re tripling our team size and our footprint.”

6K also added former U.S. Congressman Joe Kennedy III to its Board of Directors. “I was connected by a mutual acquaintance to 6K, Aaron and his team,” Kennedy said. “In my first conversation with Aaron, we discussed geopolitical competition, the climate, and critical materials, and 6K offered solutions for all of them.”

“Joe brought in an excellent point of view on climate change and national security,” said Bent.

6K’s UniMelt technology addresses a number of the existing shortcomings that make U.S. battery material production so difficult. “Virtually nobody produces here because of the cost and unsustainability,” Bent explained. “No existing technology is clean. 6K fixes that, and creates a circular economy.” The company’s plasma production compresses what was formerly a two- to three-day battery chemistry process to two seconds of plasma production.

The 6K UniMelt system.

Unlike legacy production methods, the UniMelt system creates no solid or liquid waste when producing batteries. “Just as with our metal 3D powders, we are also exploring ways to use recycled battery feedstocks, greatly reducing material costs,” Bent said. “People ask what we’re going to do with hundreds of thousands of end-of-life batteries. Recycling them [with legacy methods] is dirty, and landfilling is a terrible option. 6K addresses that problem. There’s the massive growth in the battery industry that’s currently at the expense of the environment. We have a change of message, from using polluting virgin materials to taking used batteries to make new battery materials.”

UniMelt technology is material agnostic, which offers other advantages. “One aspect of getting to independence is to be able to flex to any battery chemistry you want,” said Richard Holman, VP, Battery Products at 6K. “For example, replacing scarce minerals such as cobalt with other elements can bring huge increases in battery capacity, but that’s difficult if not impossible to do by standard methods. Our technology will help accelerate production in-country.” Additionally, supporting a full range of potential battery chemistries can also address the common complaint about long charge times for lithium-ion batteries, as chemistries such as lithium iron phosphate combined with high-rate anodes like silicon enable charging in much shorter time periods. That full range of chemistries may eventually lead to 6K’s involvement in parallel battery technologies, such as residential batteries and grid storage.

A final advantage 6K brings to the table is in the pursuit of cost parity, and eventually superiority, to the internal combustion engine (ICE). As 6K scales its processes to full production, it predicts reductions in production costs that will enable battery cells to cost 40% less than the ICE equivalent by 2030. “It’s awfully hard to legislate a move to something that doesn’t exist,” Kennedy said. “For EVs, it’s about how do we make enough, and where will the materials come from? Without question this is symbiotic—it will take down barriers and costs. And it will take those costs down without hurting the environment. 6K will make things cheaper, better, faster and healthier. As we go through our proof of concept, that will allow policymakers to accelerate the transition.”

It’s that proof of concept that’s the focus for 6K right now. “6K is focused on creating the next generation of battery materials, and supporting future technologies,” Bent said. “We want to create partnerships to get battery plants on U.S. soil. We’ll use the core 6K technology to clean up the process and drive costs down. We’ll speed things up to develop and launch products more quickly.”

In the end, it’s about supporting the drive for cleaner transport, while also making America stronger. “The situation with rare earth elements is emblematic of our supply chain weakness,” Kennedy said. “If we don’t come up with a strategic plan, we can get squeezed. The economy has helped create that weakness, so we have to re-evaluate. We’ve learned you don’t create a whole industry around a geopolitical rival.”